Table of Contents

Benefits of Using Filament Fiber in Asphalt for Roadway Construction

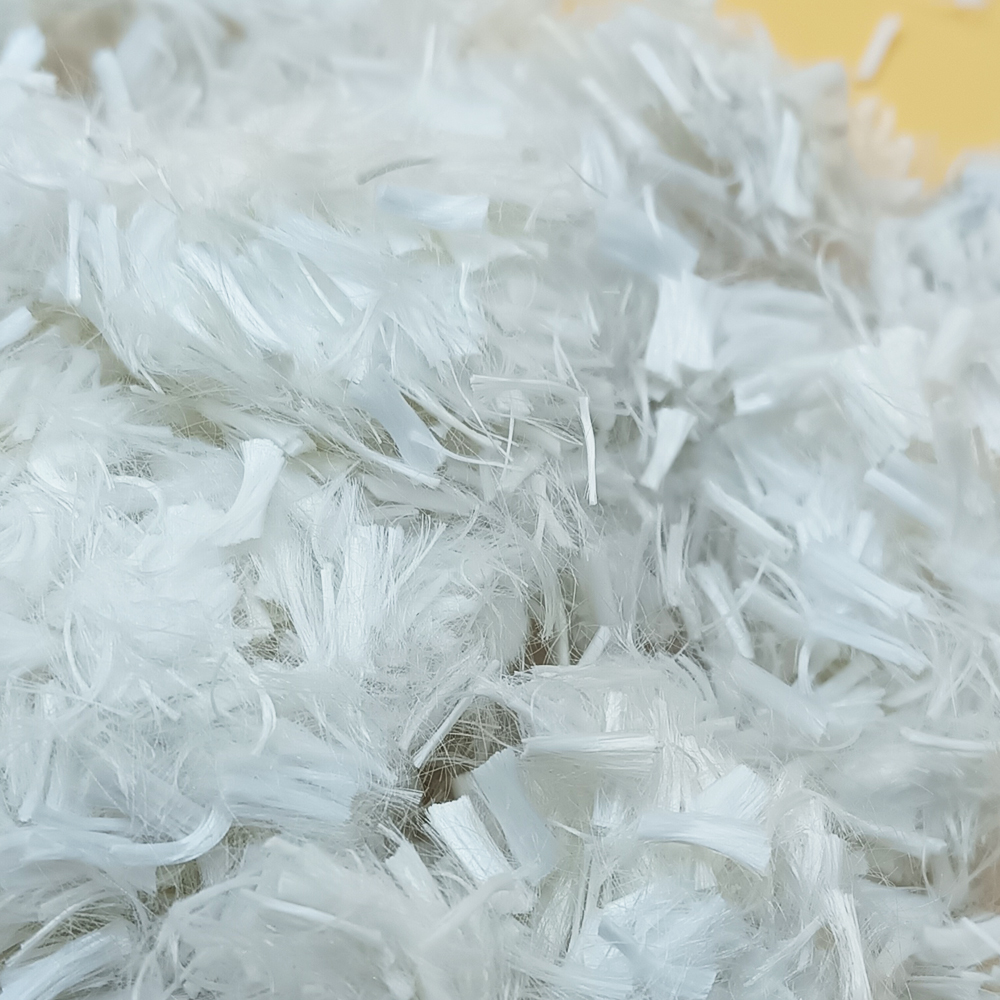

Polyethylene terephthalate (PET) filament fiber is a material that has been gaining popularity in the construction industry, particularly in the production of asphalt for roadway construction. This synthetic fiber is derived from polyester and has proven to be a valuable additive in asphalt mixtures due to its numerous benefits. In this article, we will explore the advantages of using filament fiber in asphalt for roadway construction.

One of the primary benefits of incorporating filament fiber into asphalt mixtures is its ability to enhance the overall performance and durability of the pavement. The addition of filament fiber helps to improve the tensile strength of the asphalt, making it more resistant to cracking and rutting. This, in turn, extends the lifespan of the pavement, reducing the need for frequent repairs and maintenance.

Furthermore, filament fiber helps to increase the flexibility of the asphalt, allowing it to better withstand the stresses and strains that come with heavy traffic loads. This flexibility helps to prevent the formation of cracks and potholes, which can compromise the structural integrity of the pavement. By using filament fiber in asphalt mixtures, contractors can ensure that the roadways they construct will be able to withstand the rigors of daily use for years to come.

In addition to improving the performance and durability of asphalt pavements, filament fiber also offers environmental benefits. By using this synthetic material in asphalt mixtures, contractors can reduce the amount of natural resources needed for roadway construction. This is because filament fiber is a recycled material, typically made from post-consumer Plastic Bottles. By incorporating recycled materials into asphalt mixtures, contractors can help to reduce the environmental impact of roadway construction and promote sustainability in the industry.

Another advantage of using filament fiber in asphalt for roadway construction is its ease of use. This synthetic material can be easily mixed into asphalt mixtures using standard equipment, making it a cost-effective and efficient additive for contractors. Additionally, filament fiber is lightweight and easy to transport, reducing the logistical challenges associated with incorporating additives into asphalt mixtures.

Furthermore, filament fiber is compatible with a wide range of asphalt mixtures, making it a versatile additive for contractors. Whether working on a high-traffic highway or a residential street, contractors can rely on filament fiber to enhance the performance and durability of the asphalt pavement. This versatility makes filament fiber a valuable tool for contractors looking to improve the quality of their roadway construction projects.

In conclusion, filament fiber offers numerous benefits for contractors looking to enhance the performance and durability of asphalt pavements. From improving tensile strength and flexibility to promoting sustainability and ease of use, filament fiber is a valuable additive for roadway construction. By incorporating this synthetic material into asphalt mixtures, contractors can ensure that the roadways they construct will be able to withstand the test of time and provide safe and reliable transportation for years to come.

Environmental Impact of Polyethylene Terephthalate (PET) Filament Fiber in Asphalt Roads

Polyethylene terephthalate (PET) filament fiber is a material that has been gaining popularity in the construction industry, particularly in the production of asphalt for roadway applications. This synthetic fiber is derived from Recycled Plastic bottles, making it a sustainable alternative to traditional materials. However, the environmental impact of using PET filament fiber in asphalt roads is a topic of concern that needs to be addressed.

One of the main benefits of using PET filament fiber in asphalt roads is its ability to improve the overall performance and durability of the pavement. The addition of these fibers helps to increase the tensile strength of the asphalt, making it more resistant to cracking and rutting. This, in turn, extends the lifespan of the pavement, reducing the need for frequent repairs and maintenance. As a result, the use of PET filament fiber can help to lower overall costs and reduce the environmental impact associated with road construction and maintenance.

Furthermore, the use of PET filament fiber in asphalt roads also helps to reduce the amount of waste that ends up in landfills. By repurposing plastic bottles into a valuable construction material, the demand for virgin materials is decreased, leading to a reduction in energy consumption and greenhouse gas emissions. This closed-loop Recycling process not only helps to conserve natural resources but also contributes to the circular economy by promoting the reuse of materials in a sustainable manner.

Despite these benefits, it is important to consider the potential environmental impact of using PET filament fiber in asphalt roads. One concern is the release of microplastics into the Environment during the degradation of the pavement. As the asphalt wears Down over time, the fibers may break apart and enter the soil and waterways, posing a risk to wildlife and ecosystems. To mitigate this risk, it is essential to conduct thorough research on the long-term effects of PET filament fiber on the environment and implement proper disposal and recycling practices.

| Part | Product |

| 1 | Reinforced Fiber For Road |

Another environmental consideration is the energy consumption and emissions associated with the production and transportation of PET filament fiber. While the use of recycled materials helps to reduce the carbon footprint of the pavement, the manufacturing process still requires energy and resources. To minimize the environmental impact, it is crucial to optimize production processes, use Renewable Energy sources, and reduce emissions throughout the supply chain.

In conclusion, the use of PET filament fiber in asphalt roads offers numerous benefits in terms of performance, durability, and sustainability. However, it is essential to carefully assess the environmental impact of this material and implement measures to mitigate any potential risks. By promoting responsible use and disposal practices, we can harness the full potential of PET filament fiber while minimizing its impact on the environment. As we continue to innovate and improve our infrastructure, it is crucial to prioritize sustainability and ensure that our choices align with the principles of environmental stewardship.