Table of Contents

Benefits of Using Polymer Fiber Roads for Driveways

Polymer fiber roads have been gaining popularity in recent years as a durable and cost-effective solution for driveways. These roads are made from a mixture of polymer fibers and asphalt, creating a strong and flexible surface that can withstand heavy traffic and harsh weather conditions. There are several benefits to using polymer fiber roads for driveways, including increased durability, reduced maintenance costs, and improved Safety.

| No. | Product Name |

| 1 | Asphalt Modifier |

One of the main advantages of polymer fiber roads is their durability. The polymer fibers in the mixture help to reinforce the asphalt, making it more resistant to cracking and potholes. This means that polymer fiber driveways are less likely to require repairs or resurfacing, saving homeowners time and money in the long run. Additionally, the flexibility of polymer fiber roads allows them to adapt to changes in temperature and moisture Levels, reducing the risk of damage from freeze-thaw cycles.

In addition to their durability, polymer fiber roads also offer cost savings for homeowners. Because these roads require less maintenance than traditional asphalt driveways, homeowners can save money on repairs and resurfacing over time. The increased longevity of polymer fiber driveways means that they can last for many years without needing major repairs, making them a cost-effective option for homeowners looking to invest in their property.

Another benefit of using polymer fiber roads for driveways is improved safety. The reinforced surface of polymer fiber roads provides better traction for vehicles, reducing the risk of accidents and injuries. Additionally, the smooth and even surface of polymer fiber driveways makes them easier to navigate, especially in inclement weather conditions. This can help to prevent Slips and falls, making polymer fiber driveways a safer option for homeowners and their guests.

| Nr. | Product |

| 1 | for Roadway Artificial fibers |

Furthermore, polymer fiber roads are environmentally friendly. The use of polymer fibers in the mixture reduces the amount of asphalt needed for the driveway, which can help to conserve natural resources. Additionally, the longer lifespan of polymer fiber driveways means that they require fewer repairs and resurfacing, reducing the amount of waste generated from maintenance activities. This makes polymer fiber driveways a sustainable choice for homeowners who are looking to reduce their environmental impact.

| No. | Product Name |

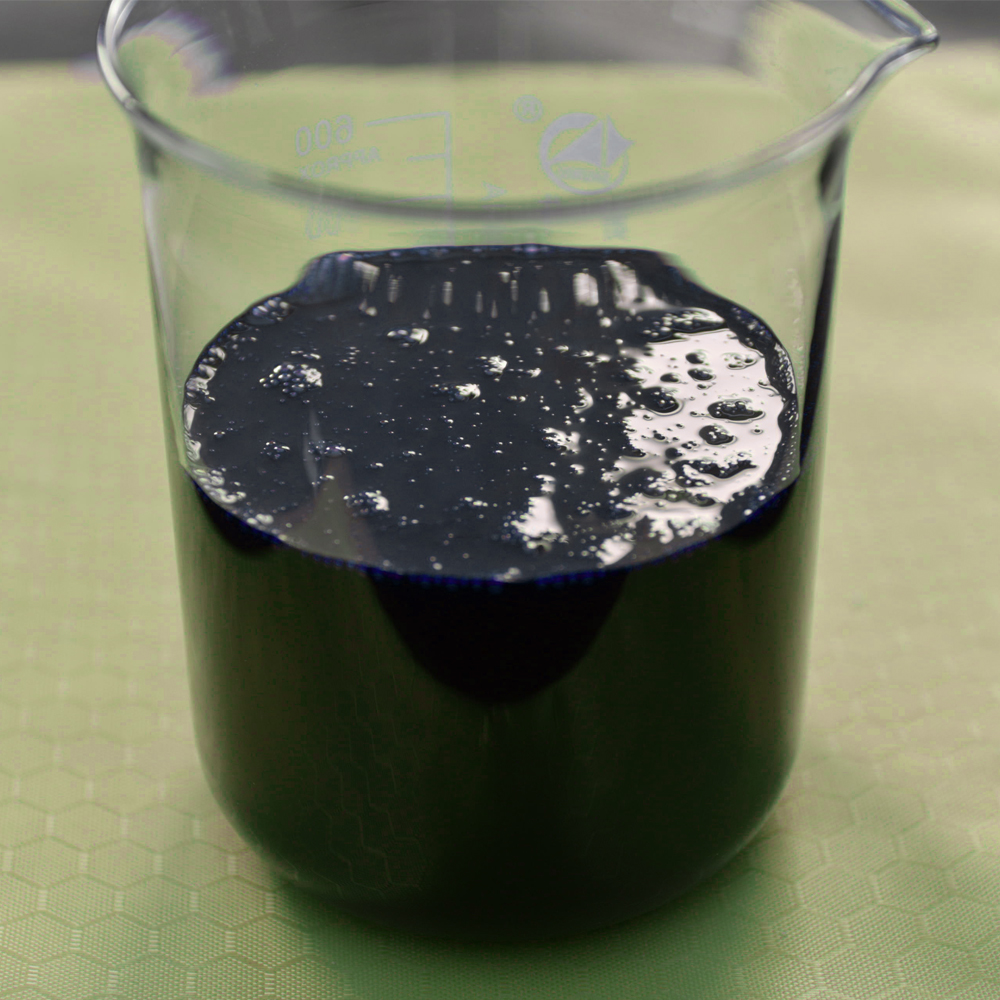

| 1 | Liquid anti-stripping Additive |

Overall, the benefits of using polymer fiber roads for driveways are clear. These roads offer increased durability, cost savings, improved safety, and environmental benefits, making them an attractive option for homeowners looking to upgrade their property. By investing in a polymer fiber driveway, homeowners can enjoy a long-lasting and low-maintenance surface that will enhance the curb appeal and value of their home for years to come.

Installation Process of Polymer Fiber Roads for Driveways

Polymer fiber roads have gained popularity in recent years as a durable and cost-effective solution for driveways. The installation process for polymer fiber roads is relatively straightforward, but it does require careful planning and attention to detail to ensure a successful outcome.

The first step in the installation process is to prepare the site for the polymer fiber road. This involves clearing the area of any debris, rocks, or other Obstacles that could interfere with the installation process. It is important to ensure that the site is level and compacted to provide a stable base for the polymer fiber road.

| Serial Number | Product Name |

| 1 | Warm Mixing bitumen additives |

| No. | Item |

| 1 | Cellulosic lignin polymer |

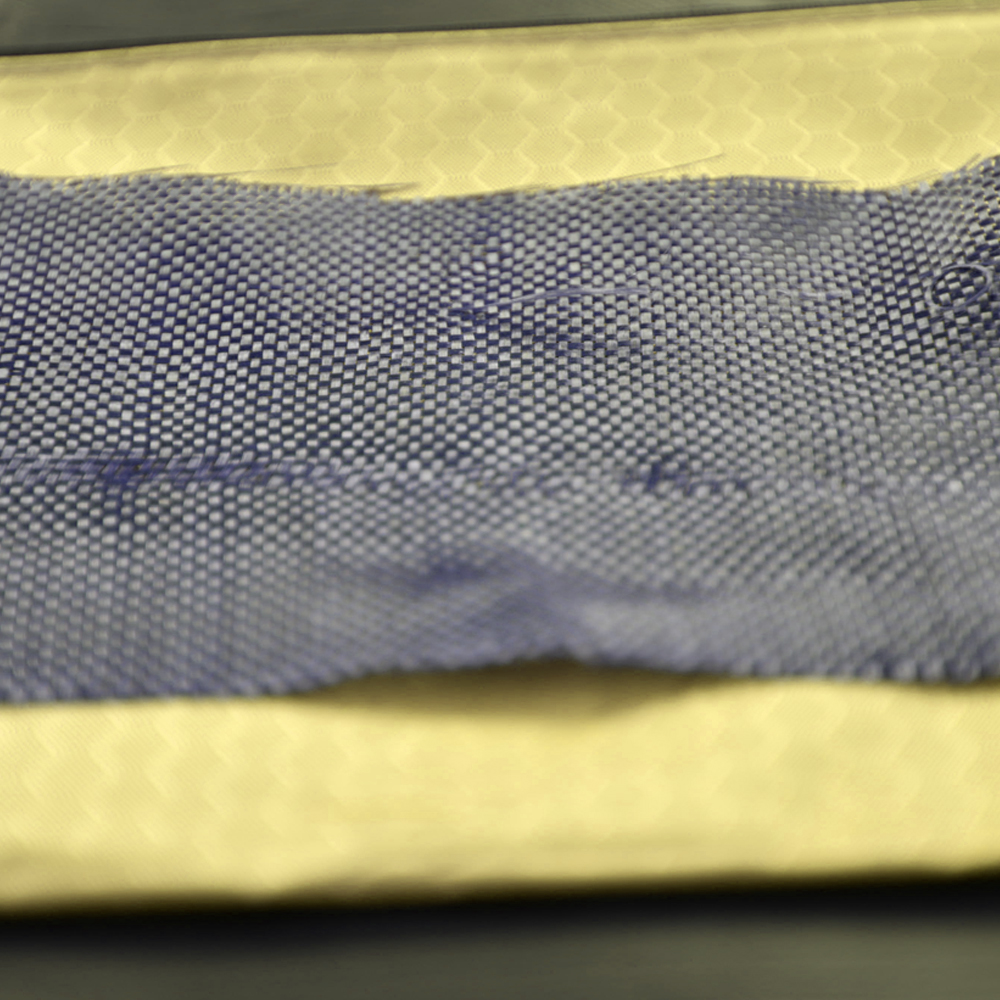

Once the site has been prepared, the next step is to lay Down a layer of geotextile Fabric. This fabric helps to prevent the growth of weeds and other vegetation that could damage the polymer fiber road over time. It also helps to provide additional stability and support for the road.

| Part | Products |

| 1 | Basalt fiber composite strands |

After the geotextile fabric has been laid down, the next step is to mix the polymer fiber material according to the manufacturer’s instructions. This material is typically a combination of polymer fibers, aggregate, and a binding agent. The mixture is then poured onto the prepared site and spread evenly using a paving machine or other equipment.

| Nr. | Article Name |

| 1 | Modulus improvement modifier for Road maintenance |

Once the polymer fiber material has been spread, it is important to compact it thoroughly to ensure a strong and durable surface. This can be done using a roller or other compaction equipment. It is important to pay close attention to this step, as proper compaction is essential for the long-term performance of the polymer fiber road.

After the polymer fiber material has been compacted, the final step is to allow it to cure. This typically takes a few days, during which time the polymer fibers will harden and bond together to create a solid surface. It is important to avoid driving or walking on the road during this time to prevent damage to the surface.

| Serial Number | Commodity Name |

| 1 | High Viscosity modifiers |

Once the polymer fiber road has cured, it is ready for use. It is important to follow any maintenance guidelines provided by the manufacturer to ensure the long-term performance of the road. This may include regular cleaning, sealing, and repairs as needed.

In conclusion, the installation process for polymer fiber roads for driveways is a relatively simple and straightforward process. By following the steps outlined above and paying attention to detail, homeowners can enjoy a durable and cost-effective solution for their driveway needs. Polymer fiber roads offer many benefits, including durability, cost-effectiveness, and ease of maintenance. With proper installation and maintenance, polymer fiber roads can provide a long-lasting and attractive surface for years to come.