Table of Contents

Benefits of Fully Synthetic Cutting Fluid for Electronics Assembly

Fully synthetic cutting fluid is a crucial component in the electronics assembly process. It plays a vital role in ensuring the efficiency and quality of the assembly process. Unlike traditional cutting fluids, fully synthetic cutting fluid offers a range of benefits that make it particularly suitable for electronics assembly.

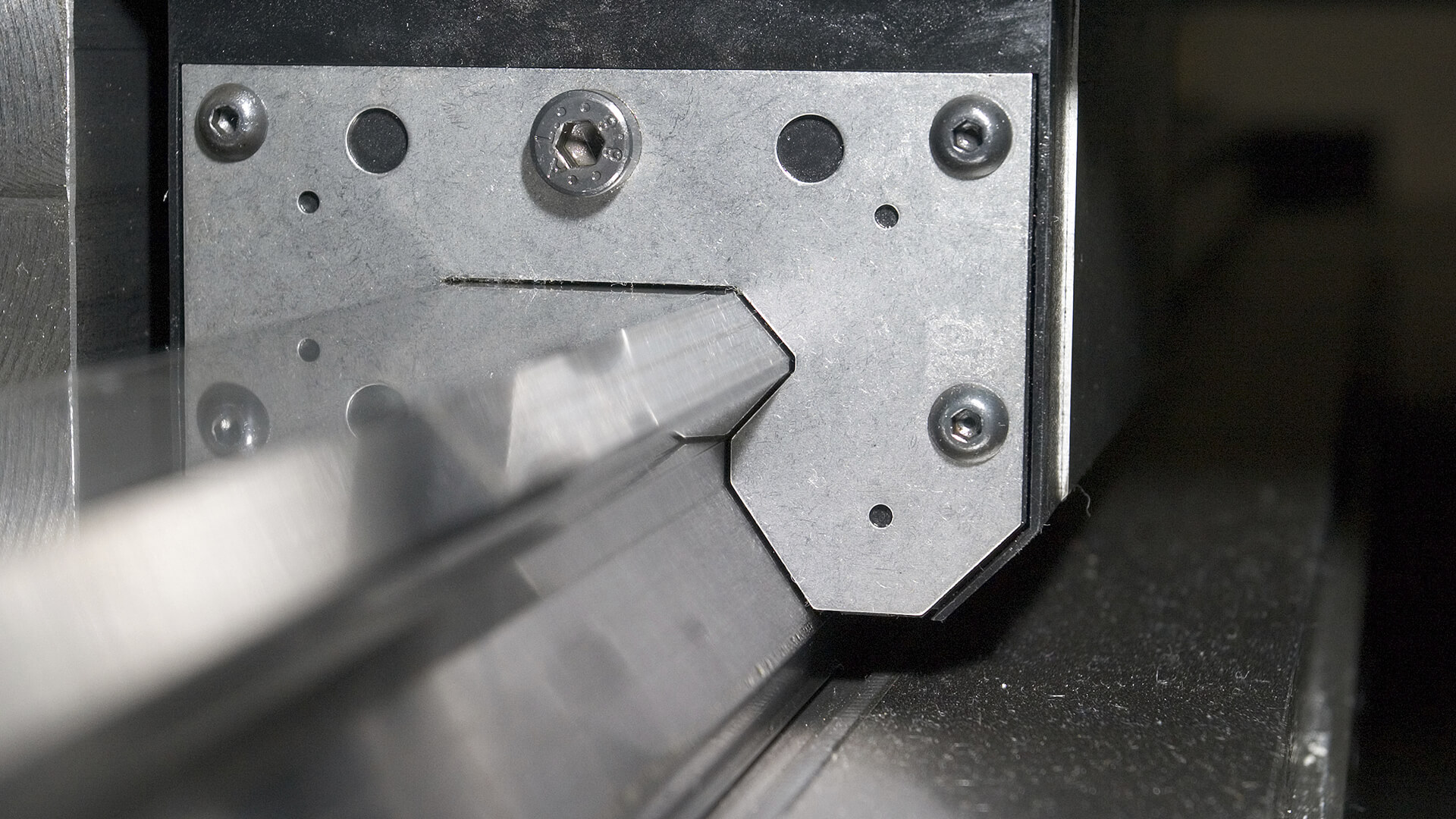

One of the key advantages of fully synthetic cutting fluid is its superior lubricating properties. This type of cutting fluid is specially formulated to provide excellent lubrication, reducing friction between the cutting tool and the workpiece. This helps to prevent wear and tear on the cutting tool, prolonging its lifespan and ensuring consistent performance. In electronics assembly, where precision is paramount, having a cutting fluid that can effectively reduce friction is essential for achieving accurate and high-quality results.

Another benefit of fully synthetic cutting fluid is its excellent cooling properties. During the electronics assembly process, cutting tools generate a significant amount of heat, which can Lead to thermal damage to the workpiece. Fully synthetic cutting fluid is designed to dissipate heat effectively, keeping the workpiece at a stable temperature and preventing overheating. This not only helps to protect the workpiece from damage but also ensures that the cutting tool operates at optimal efficiency.

Fully synthetic cutting fluid is also known for its excellent corrosion protection properties. Electronics assembly often involves working with sensitive components that are susceptible to corrosion. Fully synthetic cutting fluid forms a protective barrier on the workpiece, preventing moisture and other corrosive agents from coming into contact with the surface. This helps to extend the lifespan of the workpiece and ensures that the final product meets the required quality standards.

In addition to its lubricating, cooling, and corrosion protection properties, fully synthetic cutting fluid is also environmentally friendly. Unlike traditional cutting fluids, which often contain harmful Chemicals and additives, fully synthetic cutting fluid is made from biodegradable materials that are safe for both workers and the Environment. This makes it an ideal choice for electronics assembly facilities that are committed to sustainability and reducing their environmental impact.

Furthermore, fully synthetic cutting fluid is compatible with a wide range of materials commonly used in electronics assembly, including metals, plastics, and composites. This versatility makes it a versatile and cost-effective solution for manufacturers who work with a variety of materials in their assembly processes. By using fully synthetic cutting fluid, manufacturers can streamline their operations and reduce the need for multiple cutting fluids for different materials.

Overall, fully synthetic cutting fluid offers a range of benefits that make it an ideal choice for electronics assembly. From its superior lubricating and cooling properties to its excellent corrosion protection and environmental friendliness, fully synthetic cutting fluid is a versatile and effective solution for manufacturers looking to optimize their assembly processes. By incorporating fully synthetic cutting fluid into their operations, manufacturers can achieve higher Levels of efficiency, quality, and sustainability in their electronics assembly processes.

| Trade Mark | Name |

| www.mogenoils.com | Lubes |