Table of Contents

Benefits of Using Steel Back Plates for Transportation Brake Pads in Workshop Settings

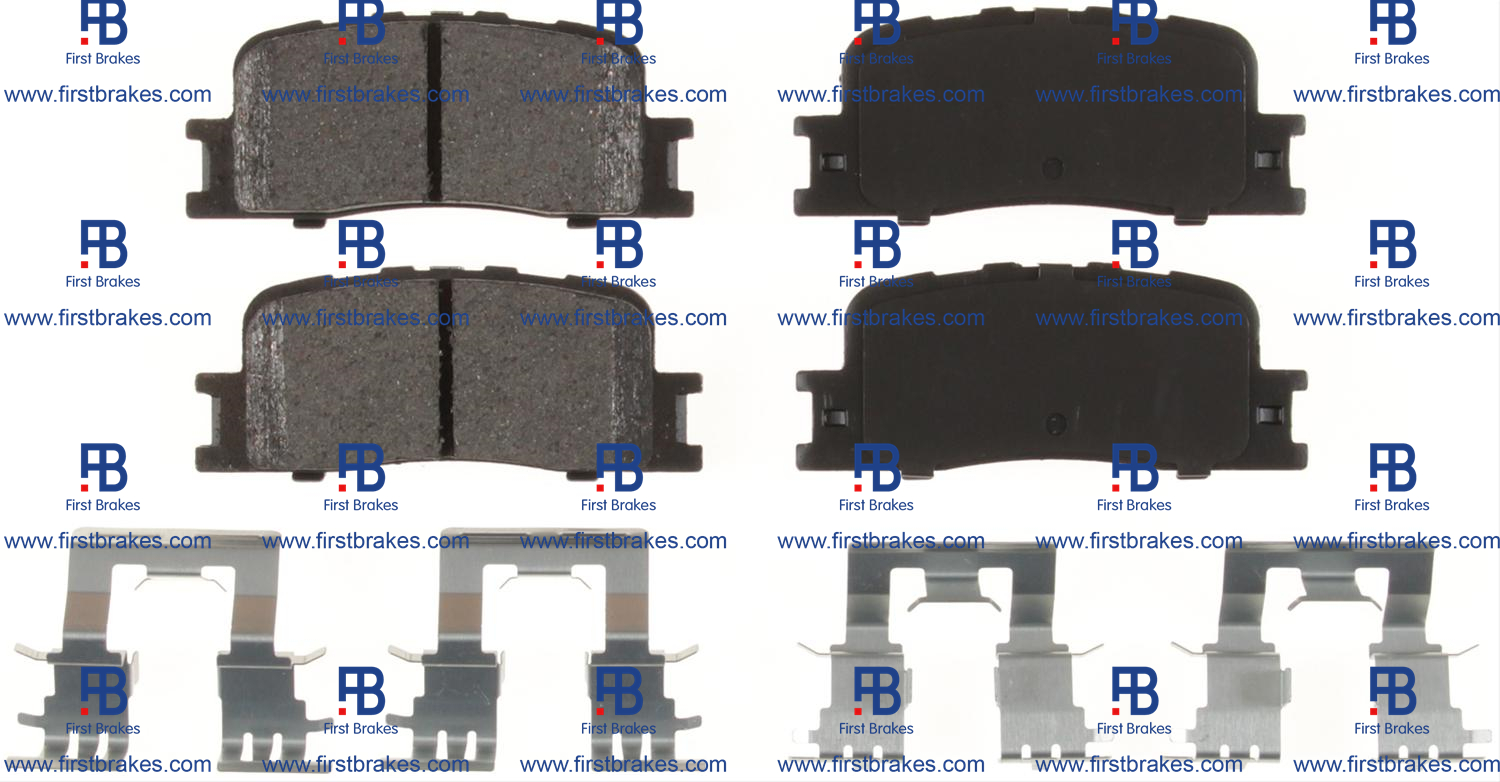

Transportation brake pads are a crucial component in ensuring the Safety and efficiency of vehicles on the road. These pads are responsible for slowing Down or stopping a vehicle by creating friction against the brake rotor. One key element of transportation brake pads is the steel back plate, which provides structural support and stability to the brake Pad. In workshop settings, using steel back plates for transportation brake pads offers a range of benefits that can improve the overall performance and longevity of the brake system.

One of the primary advantages of using steel back plates for transportation brake pads is their durability. Steel is known for its strength and resilience, making it an ideal material for withstanding the high temperatures and pressures that brake pads are subjected to during operation. Steel back plates are less likely to warp or deform under extreme conditions, ensuring that the brake pads maintain their shape and effectiveness over time. This durability translates to longer-lasting brake pads that require less frequent replacement, saving time and money for workshop owners and operators.

In addition to their durability, steel back plates also provide enhanced thermal conductivity. When a vehicle’s brakes are engaged, friction is generated between the brake pad and rotor, resulting in heat buildup. Steel back plates help to dissipate this heat more effectively, preventing the brake pads from overheating and losing their effectiveness. By maintaining a consistent temperature, steel back plates can improve the overall performance of the brake system and reduce the risk of brake fade, which can compromise the safety of the vehicle.

Furthermore, steel back plates offer superior noise and vibration damping properties compared to other materials. When brakes are applied, vibrations and noise can be generated as the brake pad comes into contact with the rotor. Steel back plates help to absorb and dampen these vibrations, resulting in a smoother and quieter braking experience for drivers. This not only enhances the comfort of the vehicle occupants but also reduces wear and tear on other brake components, such as calipers and rotors.

Another benefit of using steel back plates for transportation brake pads in workshop settings is their compatibility with a wide range of brake pad formulations. Steel back plates can be paired with various friction materials, such as organic, semi-metallic, or ceramic compounds, to meet the specific performance requirements of different vehicles and driving conditions. This versatility allows workshop operators to offer a diverse range of brake pad options to their customers, ensuring that they can find the right solution for their vehicle’s needs.

In conclusion, steel back plates are an essential component of transportation brake pads that offer numerous benefits for workshop settings. From their durability and thermal conductivity to their noise and vibration damping properties, steel back plates play a critical role in enhancing the performance and longevity of brake systems. By choosing brake pads with steel back plates, workshop operators can provide their customers with reliable and high-quality brake solutions that prioritize safety and efficiency on the road.