Table of Contents

Benefits of Using Steel Wire Rope Cable for Industrial Applications

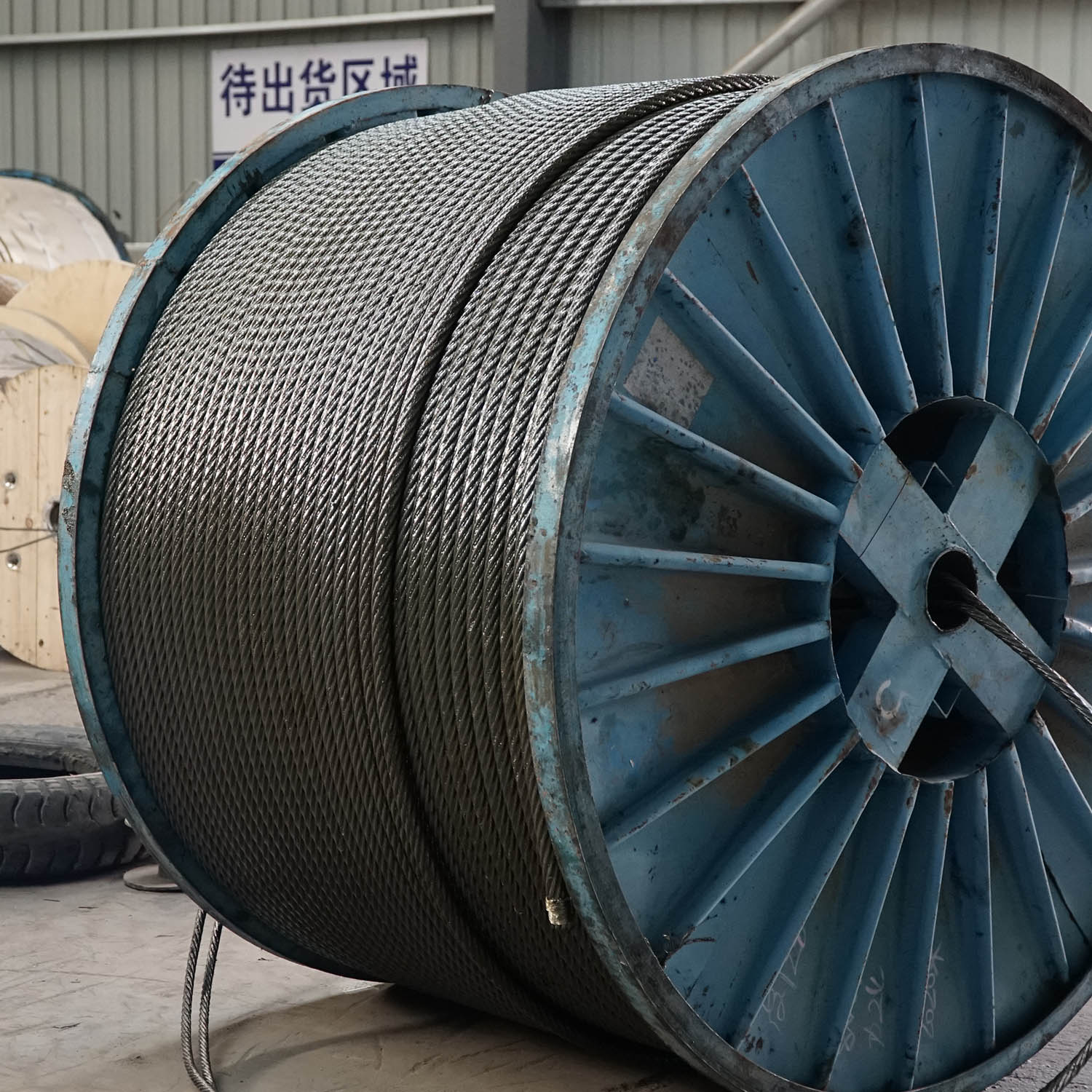

Steel wire rope cables have been a staple in industrial applications for many years due to their durability, strength, and versatility. These cables are made up of multiple strands of steel wire twisted together to form a strong and flexible rope that can withstand heavy loads and harsh conditions. One of the main benefits of using steel wire rope cables is their high tensile strength, which allows them to support heavy loads without stretching or breaking.

In addition to their strength, steel wire rope cables are also highly resistant to corrosion, making them ideal for use in marine environments where exposure to saltwater can cause other types of cables to deteriorate quickly. This resistance to corrosion is due to the fact that steel wire rope cables are typically made from Stainless Steel, which contains chromium that forms a protective Oxide layer on the surface of the cable, preventing rust and corrosion from forming.

Another benefit of using steel wire rope cables is their flexibility, which allows them to be easily manipulated and bent around corners without compromising their strength. This flexibility makes them ideal for use in a wide range of applications, from lifting and rigging to mooring and towing. In fact, steel wire rope cables are commonly used in the maritime industry for mooring ships and securing cargo due to their strength and durability.

When it comes to choosing the right steel wire rope cable for your industrial application, there are a few factors to consider. The diameter of the cable, for example, will determine its strength and load-bearing capacity. Thicker cables are able to support heavier loads, while thinner cables are more flexible and easier to work with.

The construction of the cable is also an important consideration. Some cables are made up of a single strand of steel wire, while others are made up of multiple strands twisted together. The construction of the cable will affect its flexibility, strength, and resistance to abrasion.

When it comes to pricing, stainless steel wire rope cables are typically more expensive than other types of cables due to their high quality and durability. However, the long-term benefits of using stainless steel wire rope cables, such as their resistance to corrosion and longevity, often outweigh the initial cost.

In conclusion, steel wire rope cables are an excellent choice for industrial applications due to their strength, durability, and versatility. Whether you are lifting heavy loads, securing cargo at sea, or rigging equipment, steel wire rope cables are sure to meet your needs. With their high tensile strength, resistance to corrosion, and flexibility, steel wire rope cables are a reliable and cost-effective solution for a wide range of industrial applications.

How to Choose the Right Diameter and Construction of Stainless Steel Wire Rope for Different Applications

Stainless steel wire rope is a versatile and durable material that is commonly used in a variety of applications, from construction and rigging to marine and industrial settings. When choosing the right diameter and construction of stainless steel wire rope for a specific application, it is important to consider factors such as load capacity, flexibility, and corrosion resistance.

One of the key considerations when selecting a stainless steel wire rope is the diameter of the rope. The diameter of the wire rope will determine its strength and load capacity, as well as its flexibility and ease of handling. In general, larger diameter wire ropes are stronger and have a higher load capacity, while smaller diameter ropes are more flexible and easier to work with.

When choosing the diameter of a stainless steel wire rope, it is important to consider the specific requirements of the application. For example, in a marine setting where the wire rope will be used for mooring or towing, a larger diameter rope may be necessary to handle the heavy loads and harsh conditions of the sea. On the other hand, in a construction or rigging application where flexibility and ease of handling are more important, a smaller diameter rope may be more suitable.

In addition to diameter, the construction of the stainless steel wire rope is also an important factor to consider. Stainless steel wire ropes are available in a variety of constructions, including 1×7, 1×19, and 7×19. Each construction has its own unique characteristics and is suited to different applications.

For example, a 1×7 construction consists of one strand with seven wires twisted together. This construction is relatively stiff and has a high breaking strength, making it ideal for applications where strength and durability are paramount. On the other hand, a 1×19 construction consists of one strand with 19 wires twisted together, resulting in a more flexible and easier to handle rope that is well-suited for applications where flexibility is important.

Finally, when choosing a stainless steel wire rope, it is important to consider the price. Stainless steel wire ropes can vary significantly in price depending on factors such as diameter, construction, and quality. It is important to balance cost with quality to ensure that you are getting a wire rope that meets your specific requirements and will provide reliable performance over time.

In conclusion, choosing the right diameter and construction of stainless steel wire rope for a specific application requires careful consideration of factors such as load capacity, flexibility, and corrosion resistance. By taking these factors into account and selecting a wire rope that meets your specific requirements, you can ensure that your project is completed safely and efficiently.